Rumored Buzz on Valve Gate Systems

Because of this, the product streaming into among the tertiary runners from a second jogger may consist of a greater proportion of shear-heated material contrasted to the melt flowing right into the various other of the tertiary joggers downstream from that secondary jogger. This sensation can, in some applications, cause preferential circulation to some drop areas, as well as can cause out-of-spec product from portions of a molding device.

This trouble of asymmetric division of shear-heated material has actually been acknowledged in a cold runner context; nevertheless, it has actually not been as plainly recognized in a warm runner context. That is, thaw in a warm jogger is generally much less viscous than in a chilly runner. Therefore, shear-induced home heating has actually been taken much less of a problem, as there is less resistance to shear.

Various gadgets have actually been developed to attend to the issue for both chilly runner and hot runner applications. In cool jogger shot, the mold and mildew part includes the runners in addition to the mold dental caries. The mold part is made up of 2 halves that mate with each other. All the joggers and the mold tooth cavities hinge on the plane of the breeding faces of the two fifty percents.

Cold jogger formats are generally simple in nature given that all the joggers push a typical plane. For cold jogger applications, U.S. Pat. No. 4,123,496 to Gallizia et al. discloses an equalization tool in an avenue lugging a melt circulation, where various sections of the thaw circulation are reoriented to accomplish a reasonably consistent warm distribution in the thaw flow (valve gate systems).

Rub. No. 6,077,470 to Beaumont discloses a similar gadget for achieving similar harmonizing leads to cold jogger applications. Beaumont discloses a device for achieving well balanced thaw circulation in chilly runner applications. The gadget is located upstream of the split that first creates an asymmetric circulation. Beaumont's tool relates to cold runners especially due to the fact that the device is dependent on the simple, planar nature of the cold runner mold.

Valve Gate Systems for Dummies

963,829 to Goldwin et al. reveals making use of cylindrical heating systems placed at different points in a warm runner manifold. The heating systems are positioned around the runners themselves and also heat the melt travelling through the joggers to make sure that cooler parts of the melt circulation are warmed to a temperature level comparable to the shear-heated portions of the thaw flow.

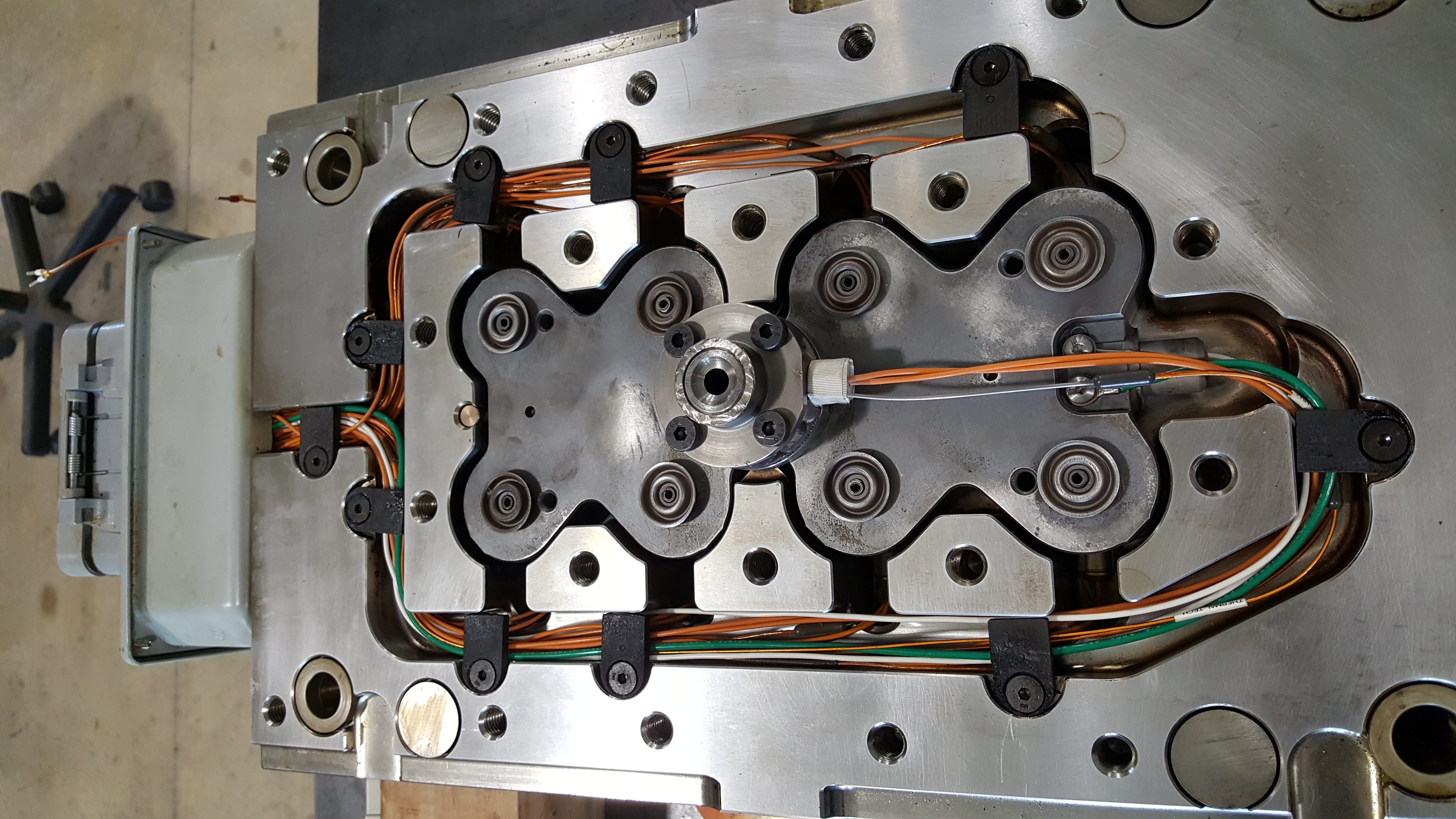

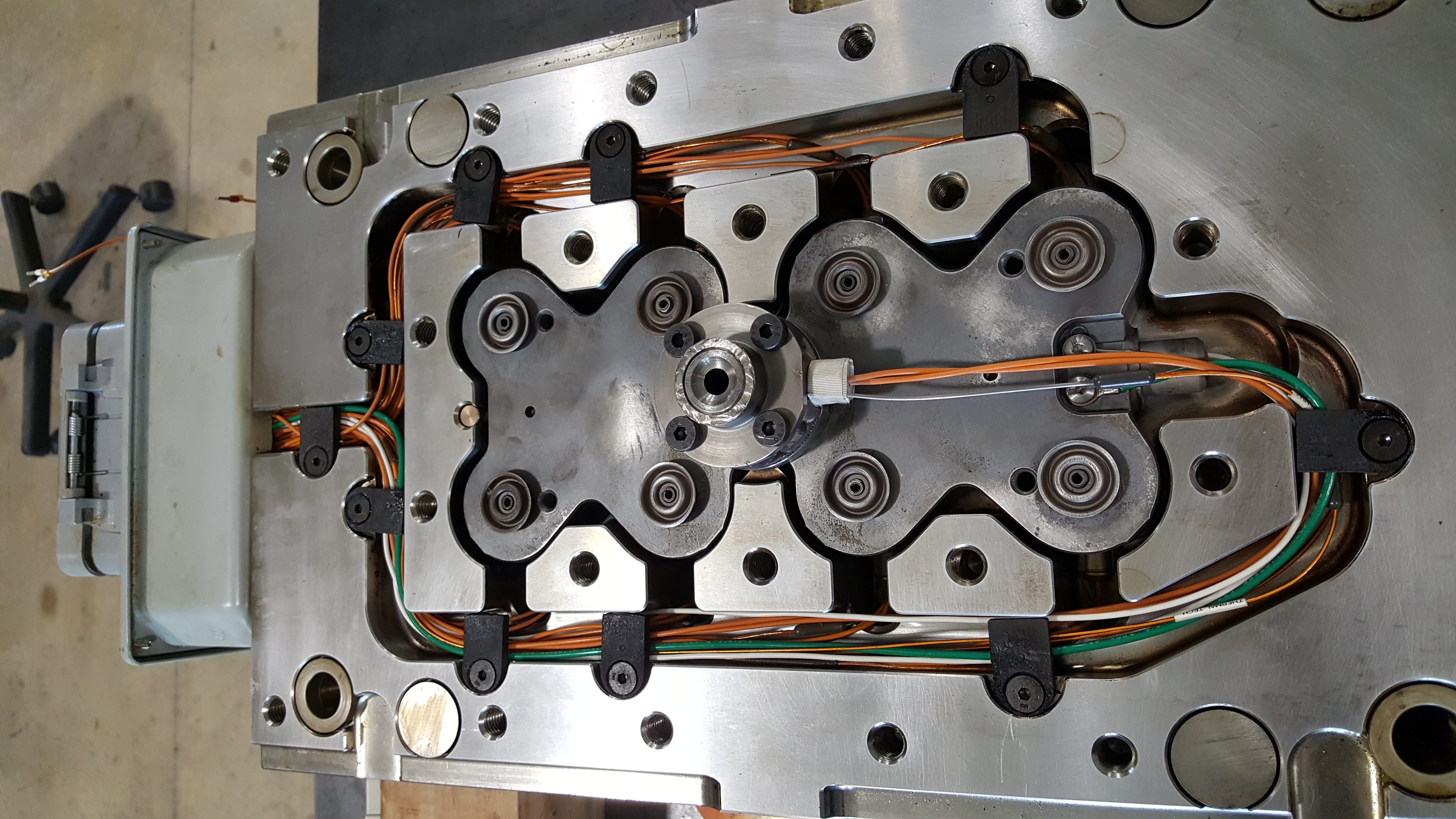

Rub. No. 5,683,731 to Deardurff et al. discloses a tool for usage in warm runner manifolds having a double X layout. The tool separates the hotter part of an asymmetric shear-heated thaw flow and rearranges it right into each jogger of the X, so that the joggers get melt having about equivalent temperature levels.

Fascination About Valve Gate Systems

This creates a reasonably uniform warmth circulation so that any downstream split in a runner system divides the heat content in the melt flow typically similarly in the joggers after the split. Numerous injection molders, nonetheless, do color adjustments throughout production runs as well as can not endure cross-contamination in between succeeding colors. Static mixers have intricate inner structures, and are therefore challenging and also time consuming to tidy, making them inadequately matched to numerous injection molding applications, such as those where color adjustments prevail as well as cross-contamination is not tolerated.

RECAP OF THE DEVELOPMENT A things of an aspect of the here and now innovation is to offer an enhanced shot molding technique. According to this first facet of the here and now innovation, there is supplied a technique of regulating a cross-sectional asymmetric condition of a laminar flowing product. The method makes up (a) giving a warm runner system, the hot runner system having an upstream melt passage, a plurality of intermediary thaw passages downstream from the upstream melt flow, and also for at least among the intermediary thaw passage, a connected pair of downstream melt flows downstream from the intermediary thaw passage; (b) supplying the laminar flowing material to the hot jogger system; (c) home heating the laminar moving material within the hot runner system; as well as, (d) for the a minimum of one intermediary thaw passage, orienting one of (i) the cross-sectional crooked condition of the laminar streaming material in the intermediary thaw flow, and (ii) the connected plurality of downstream melt passages, such that the cross-sectional crooked condition is substantially just as divided between the connected 2 downstream melt flows. valve gate systems.

official site click this link have a peek here